OUR SERVICES

K Castings offers cost effective full range shot blasting services to restore metal surfaces to their previous state or prepare metal surfaces for various coatings. Whether the part is large or small, we have a wide range of capabilities with our in-house blasting equipment. Equipped to handle everything from foundry castings to all manufactured metal parts and more, we guarantee superior service ensuring customers ease of finish application and longevity. Contact us today!

OUR MACHINES

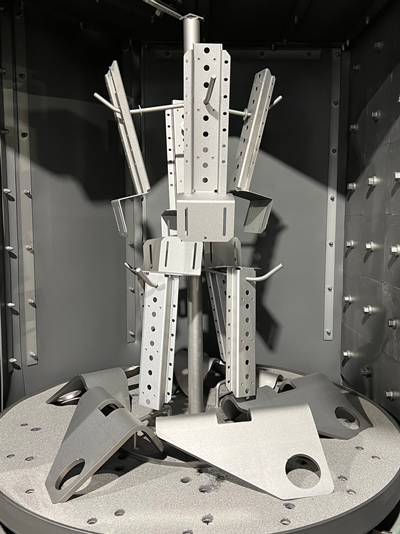

Discover precision-controlled units and media velocity, tailored to cater to a spectrum of applications from heavy-duty to delicate, guaranteeing impeccable surface finishes aligned with your exact specifications. Elevate your surface finishing game with our custom-designed jigs and hangers, maximizing surface exposure for comprehensive results.

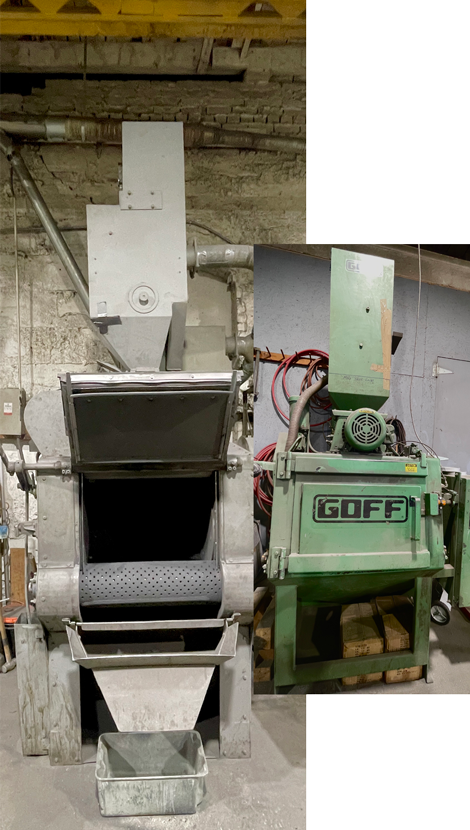

60” Diameter X 66” High-Capacity Table-Blast Machine

3 CU.FT. Tumble Blast Machines

6 CU. FT. Tumble Blast Machine

PRECISE CONTROL

All units speed controlled and media velocity controlled providing heavy to delicate applications for your perfect surface finish specifications.

Custom jigs and hangers to ensure comprehensive surface exposure.

ADVANTAGES

- Efficiently and quickly removes paint, corrosion/rust, powder coat, mill scale, primer, and other coatings

- Effective surface preparation without laborious conventional cleaning techniques such as the timely, outdated techniques of sand blasting, and use of harsh chemicals

- Reduces surface preparation time

- Promotes adhesion of preferred coatings and increases the longevity of surface coatings extensively

- Preferred method of surface preparation for powder coat and other coatings

- Restores metal parts and metal items to former state

- Removes irregularities; burrs, excess debris, and other surface contaminants without damaging the metal underneath